Segmented tension roller FMS-segFORCE®

You want to measure the tension of individual, parallel web sections in your slitter / rewinder or see the tension profile across the entire width of your web? Then the FMS-segFORCE measuring roller is the right solution for you.

Perfectly lined-up segments for measuring the tension profile or by suitable selection of segment widths and distances for tension monitoring of individual web sections. The FMS-segFORCE measuring roller is unsurpassed in its flexibility.

Your benefits

- Monitoring of smallest tension deviations from segment to segment

- Customized configuration

- Easy retrofit and installation

- Eesy system integration with PROFINET interface

Properties

- High sensitivity, wide measuring range

- Full flexibility in terms of quantity, width and position of the segments, various nominal force, full range of roll surface options

- Flexible installation options, individual overall length, simple exchange of standard idler roll, identical web path

- PROFINET interface for data processing an display via PLC

Our promise

Slitter / Rewinder

- Quick detection of faulty winding or differential friction shafts

- Clear display of different tension values of the individual webs

Coating

- Tension profile for best understanding of the process

- Fast detection and elimination of process or material related faults and malfunctions

Application in a slitter / rewinder. Do you know the winding tension of all of your single rolls?

The FMS-segFORCE measuring roller now offers producers and machine builders in the converting industry the possibility to precisely measure the web tension of individual slit webs. Especially with very thin and stretchable materials and in compact machines, this places the highest demands on the technology.

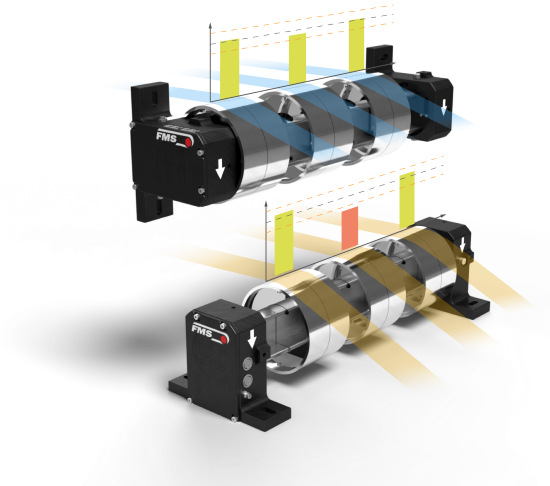

Scheme of two measuring rollers in a slitter / rewinder. The offset of the individual segments from one measuring roll to the other is clearly visible. Minimal deviations in tension between the individual web sections quickly become visible.

- Tension monitoring of each individual web section

- Highest flexibility in terms of number of segments, widths and position

- Quick detection of faulty winding or differential friction shafts

- Clear display of different tension values of the individual webs

- Tension monitoring of up to 50 individual web sections

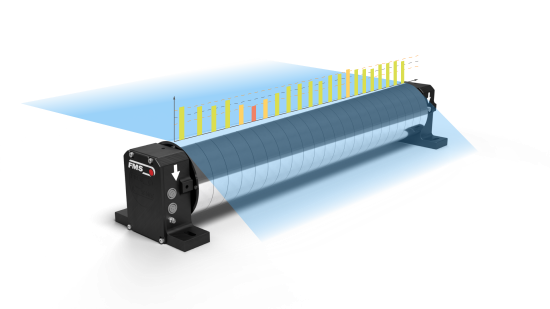

Coating. Up to 50 measuring points along one roller

With up to 50 measuring points across the web width, the FMS-segFORCE measuring roller provides a very high resolution of tension values. These are the best prerequisites for processing very sensitive materials or processes with higher requirements (process data acquisition, digital roll protocol, Industry 4.0).

The readings of the individual segments are displayed in a so-called tension profile. This allows qualified statements on process or material quality to be made at a glance. Process- or material-related faults and malfunctions can be easily identified over time. This information can help to better understand the process and optimize the entire operation accordingly.

- Up to 50 measuring points along one roller

- Highest sensitivity

- Tension profile for best understanding of the process

- Fast detection and elimination of process or material related faults and malfunctions

- Fast quality assessment of the delivered parent rolls

Download section

Questions and answers

What is the difference between conventional tension monitoring vs the FMS-segFORCE?

A roller with a set of standard loadcell can only measure the average tension across the width. Using a double-channel amplifier one can detect higher or lower tension on left or right side. With the FMS-segFORCE one gets a tension profile with up to 50 measuring points across the width of the web material. The resolution of the profile can be set by selecting appropriate segment width and quantity.

Where is the FMS-segFORCE applied?

One main application is in the quality control of web material. The tension profile can be used to identify defective material and exclude it from further processing steps. The causes can be determined and corrected before valuable machine hours are lost. The tension of the individual slit strips can also be measured in secondary slitter / rewinders. Deviations are directly indicated, and suitable countermeasures can be taken.