Wire and Cable Industry

Increasing cost pressure and increased quality awareness in the market are forcing cable and wire manufacturers to seek solutions to operate their existing systems more efficiently.

Go to RTM X42:

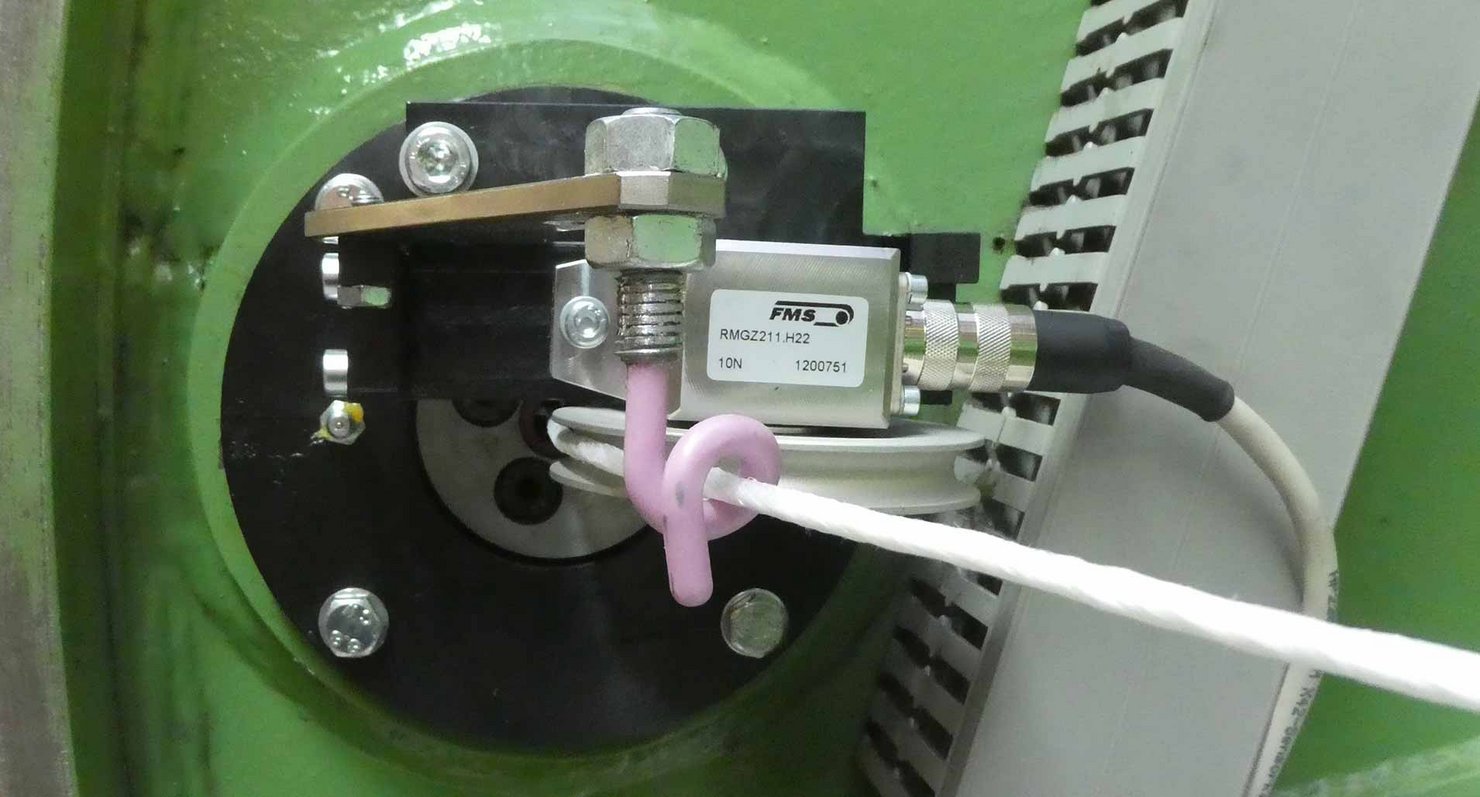

Modular Wire Tension Monitoring, Documentation and Control System for Tubular and Cage Type Stranders with Radio-Based Signal Transmission.

Go to RTM MP Plus:

Bi-Directional, Radio-Based Signal Transmission for Rotating Machinery. Analog, Digital and Encoder.

Go to FMS-cradleGUARD:

Radio-Based Signal Transmission of Safety Relevant Signals from Cradle to the Operator’s Station. (Pintle Lock, Cradle Tilt, Wire Break Detection)

Your advantages

- Reproducible process parameters

- Minimum scrap

- Lower downtimes

- Short amortization periods

Processes

- Stranding

- Bunching

- Wire drawing

Our promise

- Easy retrofitting

- Modular design

- Ease of use

- Maintenance-free with a long service life

Our products and solutions are used in a wide variety of systems and machining processes:

- Cage strander, with/without backtwist

- Tubular/fast standers

- Stranding

- Bow stranders

- Bunching

- Twisting

- Armoring

- Unwinding/winding

- Wire drawing

- High voltage (HV) power cables

- Special cables

- Cable car

- lifting gear

- winches

Challenges of the wire and cable industry.

Production errors cost money. Repairs are often time consuming or not possible. The procurement of new machines is very costly and attempts to reduce errors in the production process is often not possible with conventional technologies. A system for easy retrofitting and monitoring of the most important parameters is required.

Our solution

FMS offers its customers real added value in realizing their goals. Precise strand tension measurement/control and radio transmission of signals – essential for efficient operations management – with high productivity and the highest quality. But it does not end here.

Additional benefits

FMS goes one step further. Extensions can be used to monitor switches and sensors on the rotating machines. Especially with existing systems, this can mean a considerable increase in machine safety with little effort.

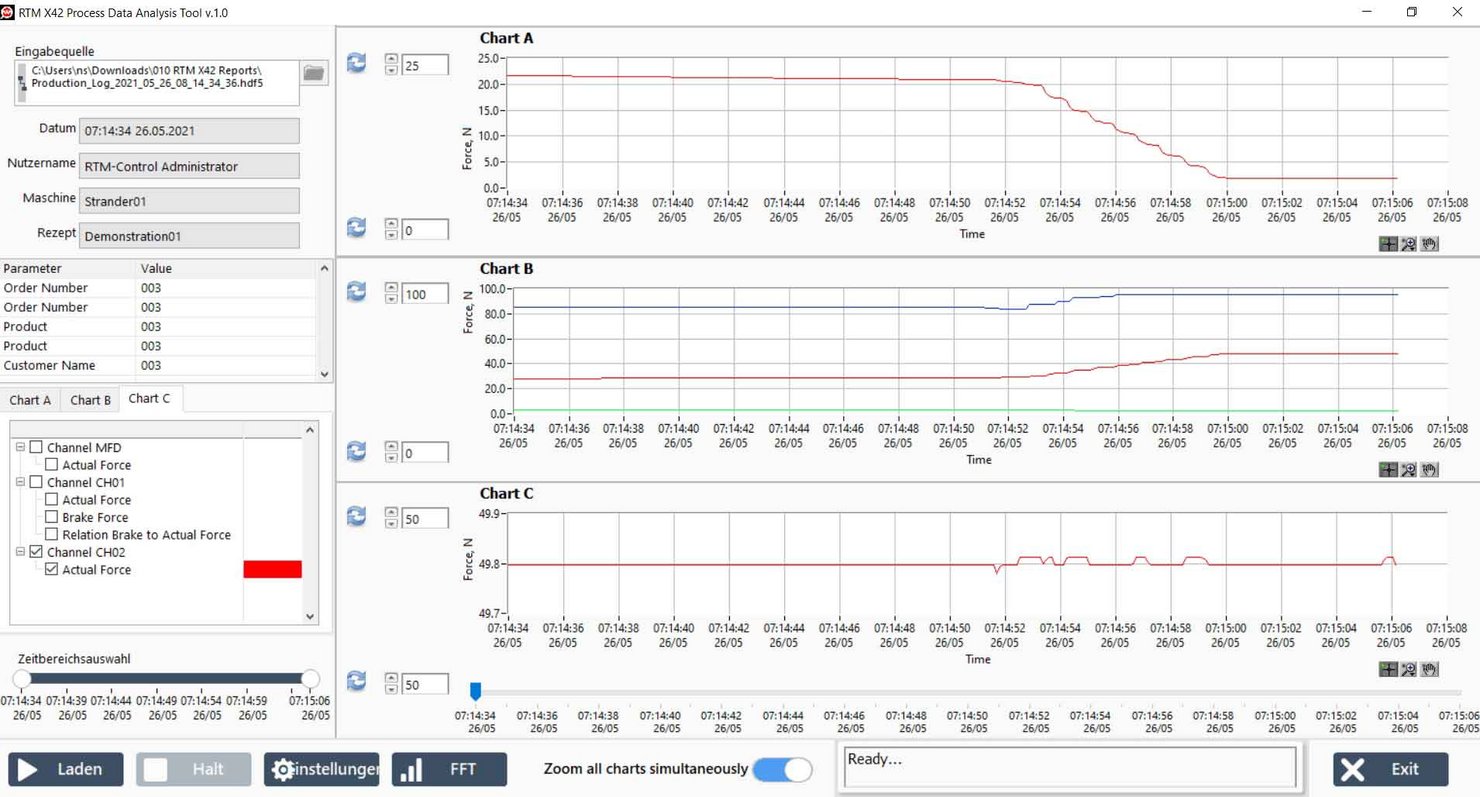

Data analysis

In addition to the technical aspects, the solutions of FMS generate measurement data that can be collected and evaluated by you for the continuous improvement of the processes or system. Use this information to save costs and to cope with the increasing international competitive pressure.

Advantage

Benefit directly from faster set-up times, consistently high product quality and reproducible process parameters. Increasing productivity, as well as improving the quality of your products lead to the customer satisfaction.

Our distribution and service partners have decades of experience in the wire and cable industry. They provide consulting, planning, delivery, installation, commissioning, development of special solutions and service for your machine.

Bartell Machinery Systems, L.L.C.

6321 Elmer Hill Road

Rome, New York 13440-9325,

USA

Tel: (315) 336-7600

Fax: (315) 336-0947

salesbartellmachinerycom